Glass industry

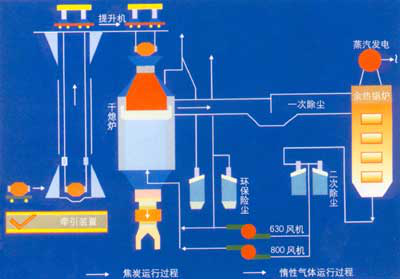

The dry quenching technique utilizes a cold inert gas (combusted exhaust gas) to exchange heat with red hot red coke in a dry quenching furnace to cool the red coke. The inert gas that absorbs the heat of the red coke transfers the heat to the dry quenching boiler to generate steam, and the cooled inert gas is then circulated by the circulating fan into the dry extinguishing furnace to cool the red coke. The steam generated by the CDQ boiler is either incorporated into the steam pipe network of the plant or sent to generate electricity. In the reverse movement, the coke is gradually cooled to below 250 ° C, and then discharged by the unloading device at the bottom of the furnace; at the same time, the inert gas (or waste flue gas) is heated to about 800 ° C, passing through the dry quenching ramp After the primary dust collector, the boiler enters the dry quenching boiler; in the boiler, the water is heated by the hot air stream to generate steam, and the gas is cooled to about 200 ° C, and then re-supplied into the dry extinguishing furnace by the circulating fan through the secondary dust removal.

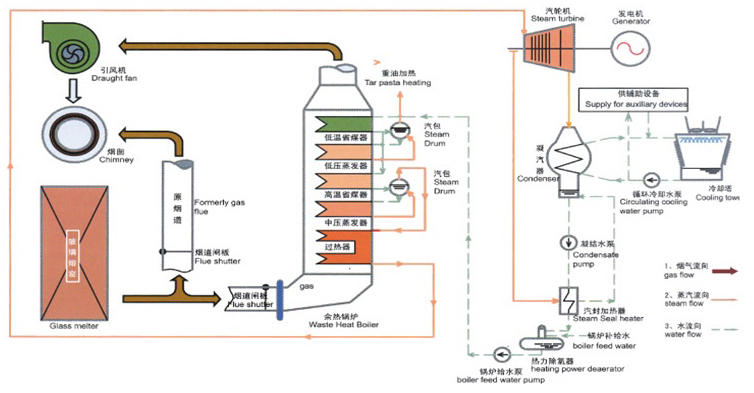

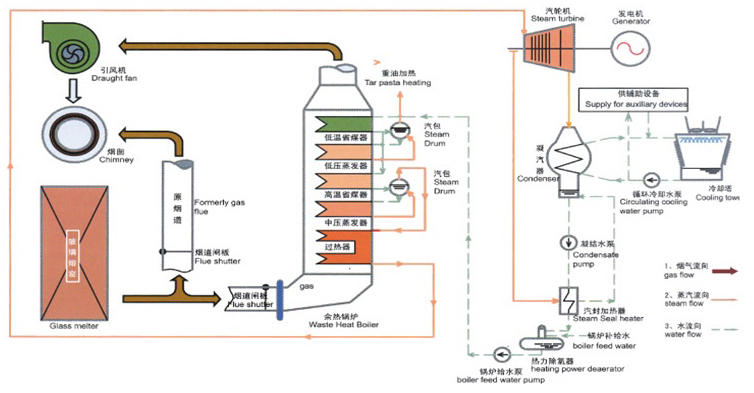

Glass kiln waste heat power generation process flow chart

Glass kiln waste heat power generation process flow chart

The dry quenching technique utilizes a cold inert gas (combusted exhaust gas) to exchange heat with red hot red coke in a dry quenching furnace to cool the red coke. The inert gas that absorbs the heat of the red coke transfers the heat to the dry quenching boiler to generate steam, and the cooled inert gas is then circulated by the circulating fan into the dry extinguishing furnace to cool the red coke. The steam generated by the CDQ boiler is either incorporated into the steam pipe network of the plant or sent to generate electricity. In the reverse movement, the coke is gradually cooled to below 250 ° C, and then discharged by the unloading device at the bottom of the furnace; at the same time, the inert gas (or waste flue gas) is heated to about 800 ° C, passing through the dry quenching ramp After the primary dust collector, the boiler enters the dry quenching boiler; in the boiler, the water is heated by the hot air stream to generate steam, and the gas is cooled to about 200 ° C, and then re-supplied into the dry extinguishing furnace by the circulating fan through the secondary dust removal.

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

Biomass boiler

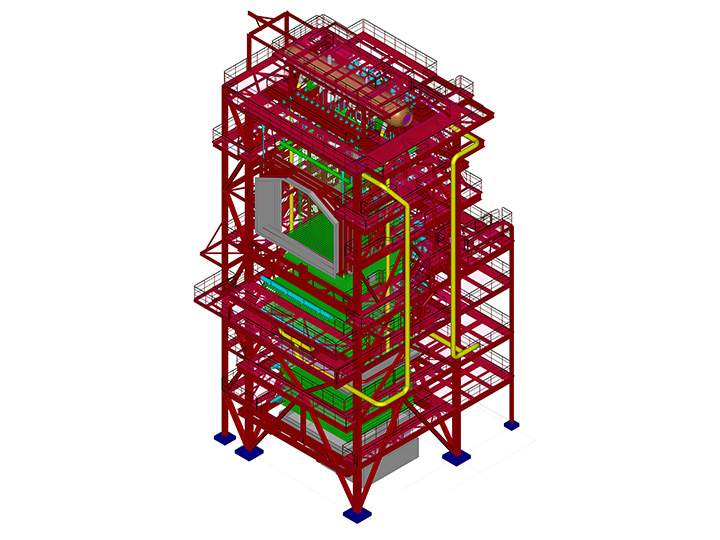

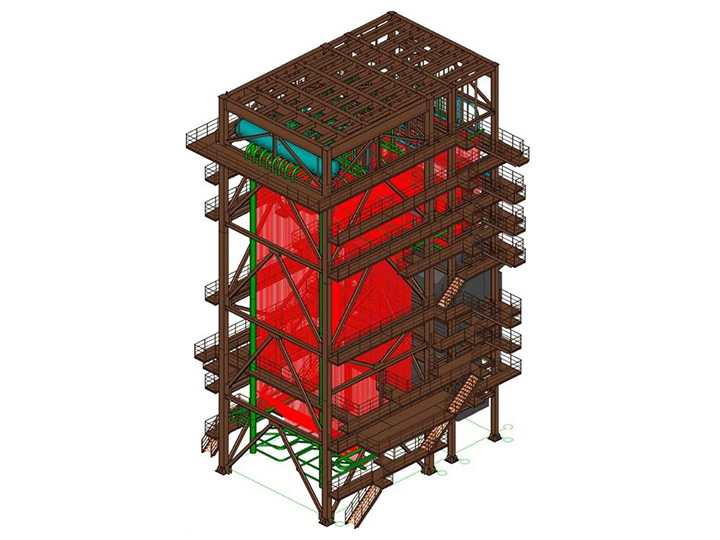

Biomass boiler  Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler

Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler  Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler

Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler  Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler

Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler